After a long road with constant repairs Roadtrek offered and came through with a replacement CS Adventurous. Even though it was a long process that was certainly stressful and aggravating, they did in the end deliver a replacement vehicle, and even offered an upgraded interior finish at no extra cost. While no company is ever perfect when dealing with customers, it was great to have Roadtrek finally offer a solution and I’m very appreciative.

Hey! Somewhere other than the repair shop!

I do have questions about this new coach, and getting an answer hasn’t been easy.

One of the main problems with the previous CS Adventurous I had, was the lackluster (at best) performance of the Alde radiant heating system. (See my previous posts) This new coach had a slightly redesigned layout, and while it’s heating much better than the last van, I question whether it was installed to proper manufacturer specifications and whether it’s working as efficiently as it should or could.

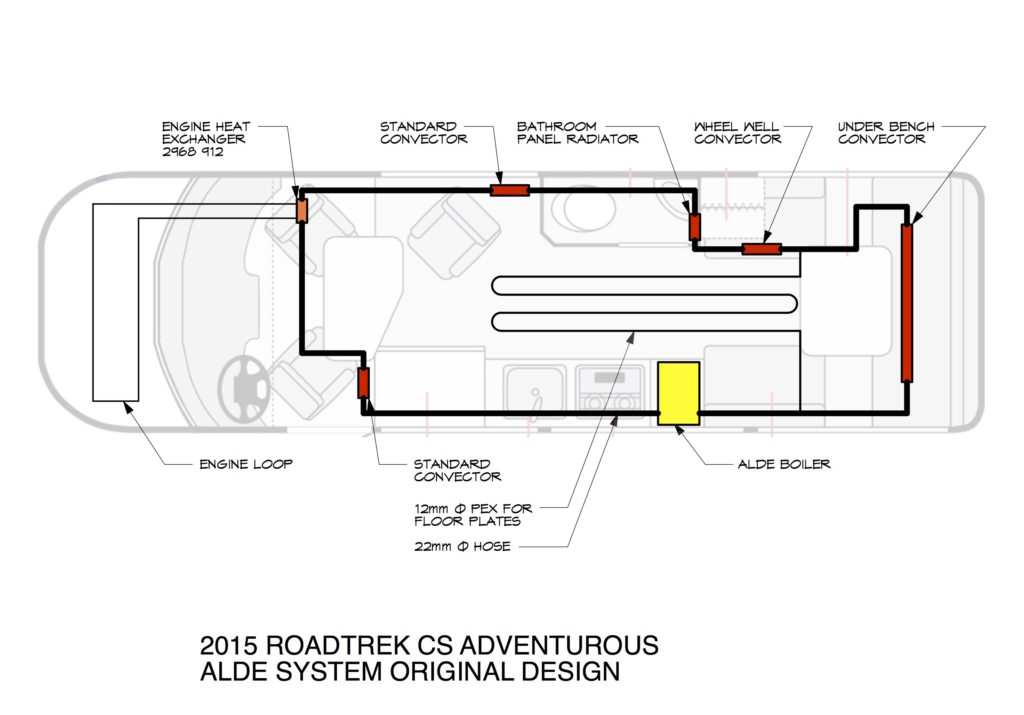

The previous system consisted of a loop of radiant tubing that ran around the coach, through convectors in various places along the way, and back to the boiler. Off of that main loop was a secondary loop that ran under the floor to warm the floor and provide additional radiating heat. For some reason, that system didn’t work – it could never heat the coach to a comfortable temperature, even after hours.

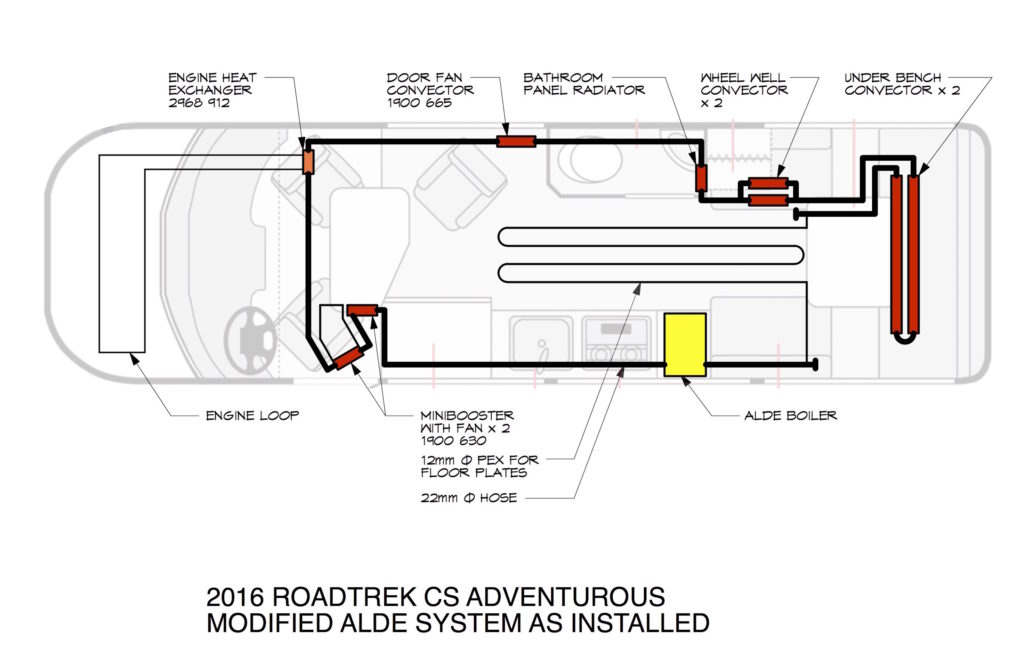

This new coach has a modified design. They added additional convectors, as well as an auxiliary fan that can be switched on and off to help circulate the heat from a set of convectors added toward the front of the van. While adding a fan to an otherwise silent radiant heating system is less than ideal, it is relatively quiet and does help to move the heat around.

The most curious change, and the thing that I’m still trying to get an answer on from the manufacturer, is the change to the main loop of radiant tubing. Instead of a main loop with a branch off that ran a second loop under the floor, this new system is a single loop – it runs out of the boiler, through the convectors, through the floor, and back to the boiler. The potential problem is the size of the piping used in the loop. The piping for the main loop runs around at 22mm thick, but it is then being reduced to 12mm when it enters and runs under the floor, and it is then enlarged again back to 22mm to reenter the boiler and complete the loop. Having experience with a home radiant heating and flooring system, as well as a very qualified engineer who designed that system, I question the reduction in diameter of the piping in the loop.

My first thought was to contact the manufacturer, Alde, and ask them if it’s acceptable practice to change pipe diameters in a loop. I had previously spoken with a representative from Alde about my first problematic van and system and figured they would be the best route to get an answer – if for nothing else, peace of mind that the system was designed and installed to their specifications and that the fact that I could practically fry eggs on the floor was a feature, not a bug. (In the previous van, the floor would never get warm – probably because it was just a branch off the main loop. In this new system, the floor was included in the main loop, so all that heated glycol was passing at it’s fully heated temperature through the floor.) Was the floor warm? You bet! Was I worried it might cause problems down the road if it was getting TOO warm? Yes.

Unfortunately, repeated calls and emails go unanswered from Alde and it’s apparently single person in the US who can answer questions about their product. Various forums talk about how helpful they are, but it’s been 3 months, and the only thing I’ve gotten was a quick email saying he was waiting to hear back from Roadtrek and would update me when he heard back. I’m still waiting.