After a long road with constant repairs Roadtrek offered and came through with a replacement CS Adventurous. Even though it was a long process that was certainly stressful and aggravating, they did in the end deliver a replacement vehicle, and even offered an upgraded interior finish at no extra cost. While no company is ever perfect when dealing with customers, it was great to have Roadtrek finally offer a solution and I’m very appreciative.

Hey! Somewhere other than the repair shop!

I do have questions about this new coach, and getting an answer hasn’t been easy.

One of the main problems with the previous CS Adventurous I had, was the lackluster (at best) performance of the Alde radiant heating system. (See my previous posts) This new coach had a slightly redesigned layout, and while it’s heating much better than the last van, I question whether it was installed to proper manufacturer specifications and whether it’s working as efficiently as it should or could.

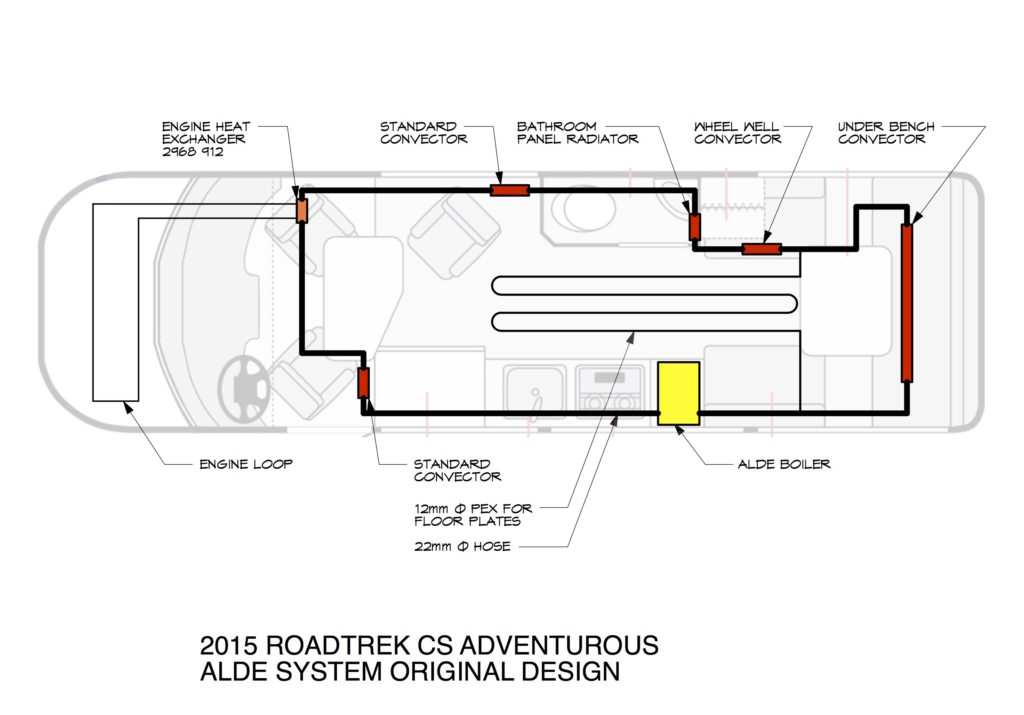

The previous system consisted of a loop of radiant tubing that ran around the coach, through convectors in various places along the way, and back to the boiler. Off of that main loop was a secondary loop that ran under the floor to warm the floor and provide additional radiating heat. For some reason, that system didn’t work – it could never heat the coach to a comfortable temperature, even after hours.

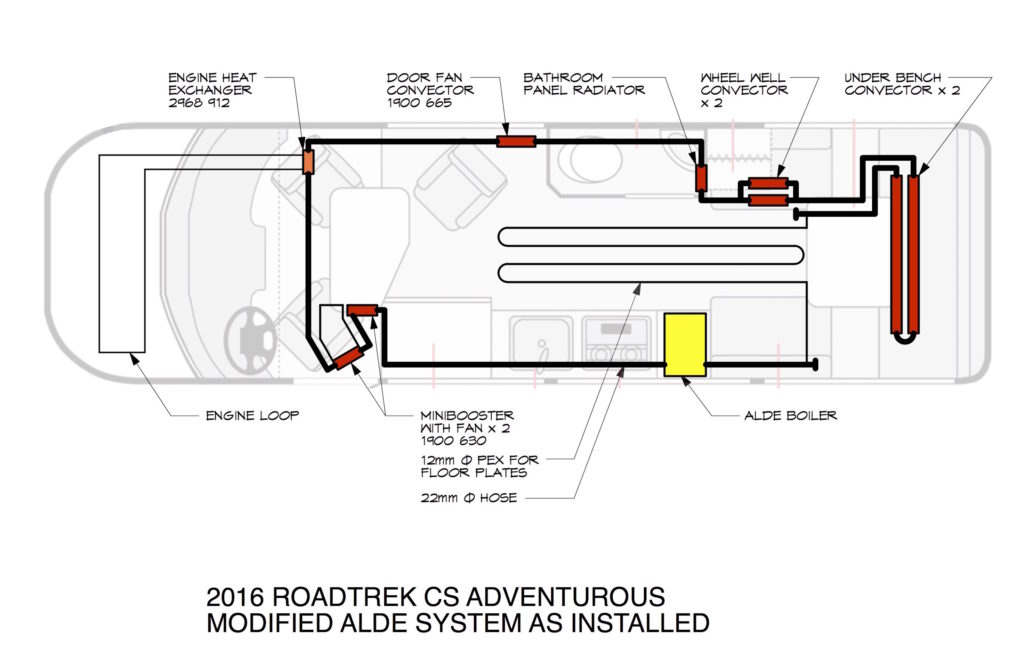

This new coach has a modified design. They added additional convectors, as well as an auxiliary fan that can be switched on and off to help circulate the heat from a set of convectors added toward the front of the van. While adding a fan to an otherwise silent radiant heating system is less than ideal, it is relatively quiet and does help to move the heat around.

The most curious change, and the thing that I’m still trying to get an answer on from the manufacturer, is the change to the main loop of radiant tubing. Instead of a main loop with a branch off that ran a second loop under the floor, this new system is a single loop – it runs out of the boiler, through the convectors, through the floor, and back to the boiler. The potential problem is the size of the piping used in the loop. The piping for the main loop runs around at 22mm thick, but it is then being reduced to 12mm when it enters and runs under the floor, and it is then enlarged again back to 22mm to reenter the boiler and complete the loop. Having experience with a home radiant heating and flooring system, as well as a very qualified engineer who designed that system, I question the reduction in diameter of the piping in the loop.

My first thought was to contact the manufacturer, Alde, and ask them if it’s acceptable practice to change pipe diameters in a loop. I had previously spoken with a representative from Alde about my first problematic van and system and figured they would be the best route to get an answer – if for nothing else, peace of mind that the system was designed and installed to their specifications and that the fact that I could practically fry eggs on the floor was a feature, not a bug. (In the previous van, the floor would never get warm – probably because it was just a branch off the main loop. In this new system, the floor was included in the main loop, so all that heated glycol was passing at it’s fully heated temperature through the floor.) Was the floor warm? You bet! Was I worried it might cause problems down the road if it was getting TOO warm? Yes.

Unfortunately, repeated calls and emails go unanswered from Alde and it’s apparently single person in the US who can answer questions about their product. Various forums talk about how helpful they are, but it’s been 3 months, and the only thing I’ve gotten was a quick email saying he was waiting to hear back from Roadtrek and would update me when he heard back. I’m still waiting.

We have the same Alde situation. Your diagrams are excellent!

I just closed the engine heat exchanger. I don’t expect much w/o the engine water pump running.

I don’t see any fix at this point for me. Did anyone ever suggest a small circulator pump in the underfloor loop?

Hi Robert. I appreciate the kind words about our diagrams. I hope our blog can help others learn from our problems, and mistakes.

I’ve been told by the service department at my dealership that in their testing they were able to boost the Alde performance by 10 degrees or more by closing that valve. In further discussion with Roadtrek and Alde, we’ve been told that the heat exchanger valve position has minimal impact on system performance, so it should remain opened. The system should have plenty to power to get you from freezing or toasty without having to mess with the valve position. In fact if you’re driving on a cold day you can run the heat exchanger pump and turn the Alde on without selecting a power source (propane or electric) and the engine does a great job of heating up the system. It does take time for the Alde to heat up and this method has worked great for us. This is one thing that Alde and Roadtrek got right!

If you’re having performance issues the culprit is likely air in the system. You have several bleeder valves that are located near each convector and in the bathroom. You can try to release any air that is built up by twisting each silver tip to the left slowly. You may hear a slight hiss followed by a solid flow of glycol. That’s when you know that air is gone. Keep a paper towel under the bleeder hole to catch any glycol that comes out.

Poor or no heat in the floor is almost always an air pocket. If you’re feeling adventurous you can try to fix this on your own as well. I don’t think this is a Roadtrek or Alde approved method, you can actually pinch off the black tube with a clamp just before the loop goes into the floor. If you have a CS, this connection is in the wheel well compartment right behind the bathroom. I just did this today and was able to get the heat working perfectly in my system.

When we spoke to the Alde representative at the 2016 Hershey show I specifically asked about adding a second pump on the floor loop, especially considering that the floor loop in a standard system is “t’d” off of the main loop. I was told that this was not necessary and with proper bleeding of the system, floor heat should not be an issue.

I wish you luck with your Roadtrek. I’m by no means an expert on the system, but have been through lots of issues that are still not resolved. Feel free to ask if you have any other questions. I’ll do my best to get you in touch with the right people if I can’t help!

Thanks for your note.

I heard the mention of pinching the hose. So today I experimented with various pinch locations. I found one in the driver’s wheel well that caused a gurgle. I knew I was onto something. Eventually I did feel heat for the first time.

In that wheel well the floor line makes a tall loop which is a perfect place for air to collect. This is where RT should put a bleeder!

The fluid flows from the Alde boiler clockwise through the van so the best location to pinch is right before it goes into the floor loop on the passenger side rear wheel well. My system also has an upward loop which is a perfect place to collect air pockets. Once you pinch you’ll here a gurgle, and for me it took several rounds of bleeding and pinching to get all of the air out. Good luck with your system! I hope with a little self help you can avoid a trip to your service center.

It looks like the “clockwise” rotation means it comes out of the floor in the back corner by the bathroom, loops back past the floor line into the bathroom convector, then comes out of the bathroom convector and into the wheel well convector. That would make your pinch location on the portion of the hose between the floor line and the bathroom wall the perfect place. Unfortunately, I have almost zero hose there. The floor hose connector is right next to the bathroom wall. That means that I can’t pinch there. It also means that the floor line has to run uphill past the water pump before going down to the floor. I don’t expect to ever get any fluid running through there. I am going to bleed the system with the Alde pump soon and see if it puts enough pressure through there to get the air out of the floor line. If not, I’ll try pinching where the line runs from the bathroom convector to the wheel well convector. If that doesn’t work, I will be contacting the dealer and Roadtrek about getting the Alde Upgrade Kit under warranty, which includes some fans as well as a non-90degree floor line connector to hopefully improve the flow. Does this sound like a good plan? So far, the only thing getting hot is the food I keep in the pantry with the Alde expansion tank!